SCREEN

DEVELOPING

New Water Recycling System PLC controlled developing sequence washing Rings or Screen Protection.

APPLICATION : The Developing Machine is used to develop rotary screens after exposing. It can maintain finest details with a repeatable standard.

MACHINE STRUCTURE : The machine body is constructed with stainless steel for a long lifetime and extended performance. It is equipped with an oscillating nozzle bar which is overlapping the spray area of the neighboring nozzle to ensure uniform developing.

Maximum Screen Width: 3500 mm

Maximum Repeat Size : 1018 mm

Voltage: 380 Volt / 3,5 KW

Water Consumption : 20 – 35 liter / screen

MACHINE SIZE:

For 3500 mm Screen – 5000 x 650 x 1400 mm (LxWxH)

For 2000 mm Screen – 3550 x 650 x 1400 mm (L x W x H)

- Easy to use

- Repeatable quality

- Adjustable pressure UV free backlight

- Water saving

- Long lasting nozzle

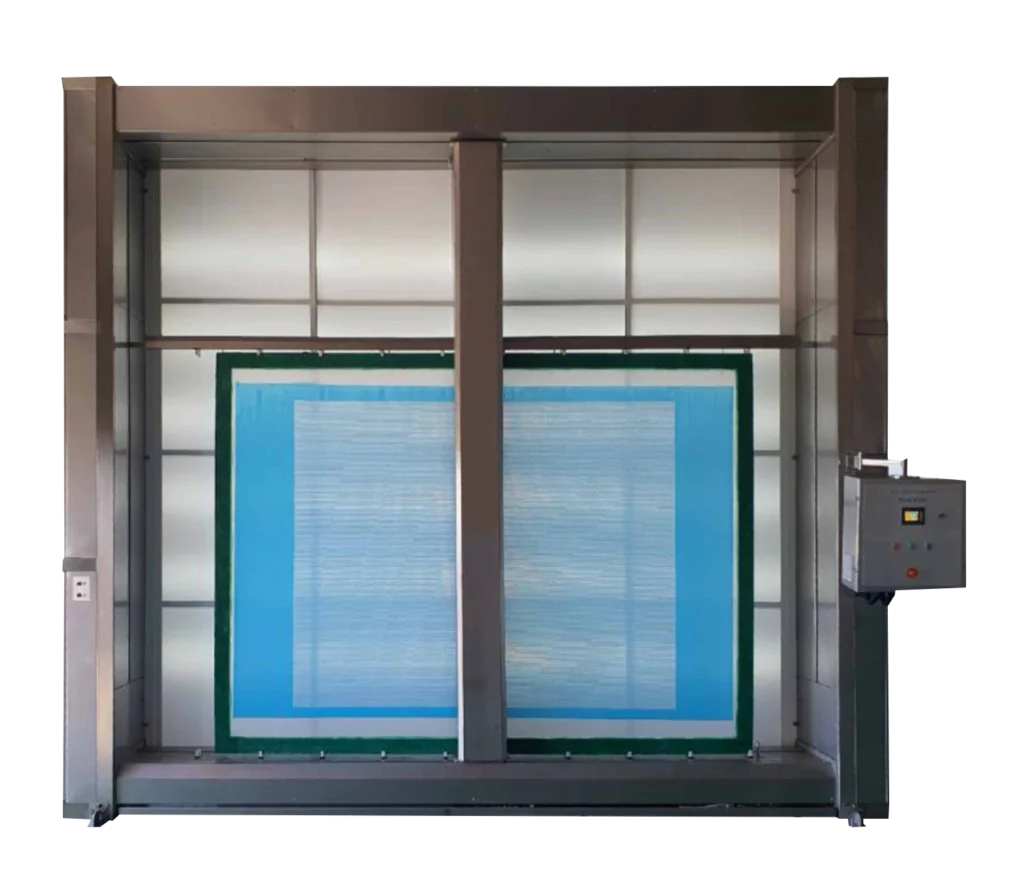

APPLICATION : The Developing Machine is used to develop flat screen in various sizes after exposing.

It can maintain the finest details with a repeatable standard.

MACHINE STRUCTURE : The machine body is constructed with stainless steel for a long lifetime and extended performance. It is equipped with an oscillating nozzle bar which is overlapping the spray area of the neighboring nozzle to ensure uniform developing.

Maximum Screen Width :7000 mm

Maximum Repeat Height : 4000 mm

Voltage: 380 Volt / 8,0 KW / 20 A

Water Consumption : 20 – 35 liter/min

(size – 2000 x 3000 mm)

Optional for high pressure cleaning after printing