Chemical

Free Rotary

Originally introduced in 1999 by CST GmbH from Germany, this technology has been sold worldwide. Nova Inter Tech was the progenitor for this new technique, using it to support rotary printers with a pollution free recycling service. The development and refining of this process has never stopped for us and our target is and always will be to encourage all rotary printers to use this technique to save our environment and to protect the workers health.

In the past using chemical stripping, the lifetime of a screen was drastically reduced because the acid inside the stripping agent corrodes the surface of the nickel screen.(see images left) Due to the strong acid the nickel screen gets thinner and more brittle and the individual mesh will be disfigured. As a consequence high quality printing is not possible with chemical stripping.

We are using only high pressure water to remove the photo emulsion from a nickel screen. With this technique we do not damage the surface or structure of the screen. If the rotary screen is handled carefully during the printing process, it is possible to re-use the screens far more often. As a result the printer can save in the cost of screens dramatically and also improve printing quality.

Selecting the best possible screen was always a balancing act between cost and quality. Now we are able to use the best quality screens because we can recycle them multiple times.

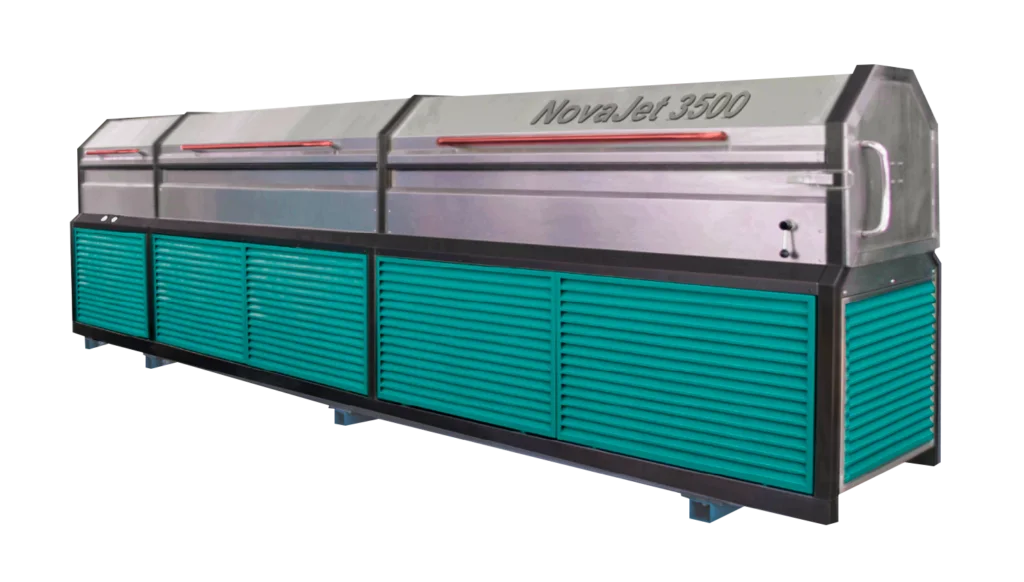

On average the water consumption is it about 40-60 litres per screen which can be reduced by using a recycling system. Also the use of nozzles and others spare parts is reduced drastically in our new model by optimising the pump and filtration systems.