Now that you know how NovaJet works, let’s see why more textile mills are shifting to this clean and safe method.

1 Better for the Planet

NovaJet is 100% chemical-free.

This means:

- no chemical purchase

- no chemical disposal

- no pollution

- safe for environment

Mills that use NovaJet can proudly say they support eco-friendly textile production.

2 Safe and Healthy for Workers

No harmful acids.

No burning smell.

No dangerous fumes.

Your staff can work safely and confidently.

This improves productivity and reduces health risks.

3 Saves Money in the Long Run

NovaJet helps you save money through:

- longer screen life

- no chemical cost

- less screen damage

- lower waste

- faster cleaning time

Cleaner screens = Better printing quality = Happier customers.

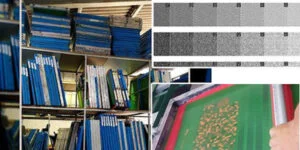

4 Consistent Printing Quality

Because the screens remain strong and the mesh stays intact, mills get:

- sharper prints

- smooth colour flow

- fewer defects

- repeatable results

Your customers get the same quality on every order.

Final Thoughts

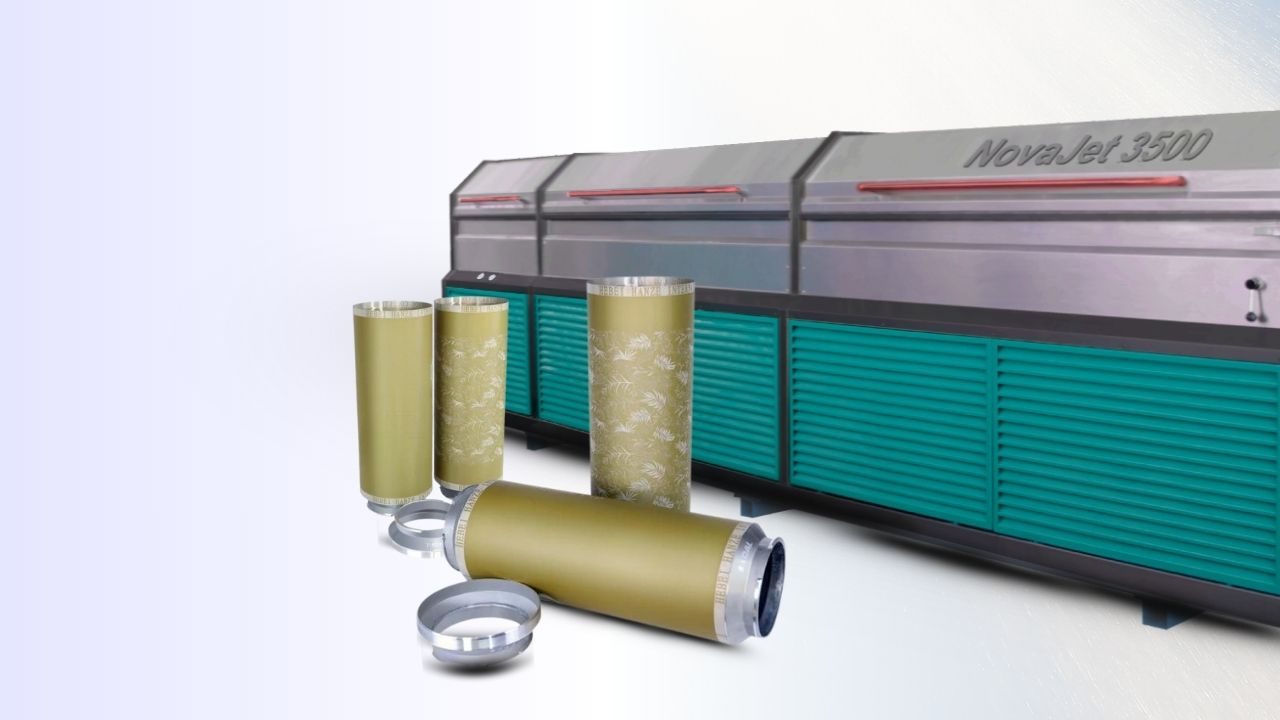

NovaJet is not just a machine – it’s a cleaner, safer and smarter way to handle rotary screen recycling. It helps mills adopt modern, sustainable and cost-efficient production.

Want a demo or pricing for NovaJet?

Call Us Now: +91 9227884022 or Send an Enquiry on Our Website