In textile printing, rotary screens play a major role in making beautiful designs on fabric. These nickel-based screens are expensive and need to be reused many times. But before they can be used again, the old photo-emulsion layer must be removed completely — and that’s where most mills face problems.

For decades, screen recycling has depended on strong chemicals, which create health risks, damage machines, and harm the environment. Today, mills are looking for safe, clean and cost-saving options. That’s where NovaJet’s chemical-free screen recycling technology is changing everything.

The Power of Water: A Cleaner and Safer Way to Recycle Rotary Screens

In textile printing, rotary screens play a major role in making beautiful designs on fabric. These nickel-based screens are expensive and need to be reused many times. But before they can be used again, the old photo-emulsion layer must be removed completely — and that’s where most mills face problems.

For decades, screen recycling has depended on strong chemicals, which create health risks, damage machines, and harm the environment. Today, mills are looking for safe, clean and cost-saving options. That’s where NovaJet’s chemical-free screen recycling technology is changing everything.

Why Traditional Screen Recycling Is a Problem

Earlier, the most common way to clean rotary screens was to soak them in a mixture of corrosive acids and solvents. While this process removed the emulsion, it also came with serious drawbacks:

1. Unsafe for Workers

Traditional stripping chemicals include chromic acid, chloric acid, phenols, and other harmful substances. These are known to cause skin burns, breathing issues and long-term health risks. Many of these chemicals are banned in countries across Europe because of their harmful effects.

2. Screens Become Weak & Damaged

Acid slowly eats away the nickel surface of the screen. Over time, the screen becomes thinner, more fragile and loses mesh quality. This directly affects print clarity and increases screen-replacement costs.

3. High Environmental Impact

Chemical stripping creates toxic waste that cannot be thrown out normally. Mills must spend money on safe disposal, and even then, it causes water and soil pollution.

For an industry moving towards sustainability, safety, and efficiency, this old method is no longer suitable.

NovaJet: A New Way Forward With Only Water

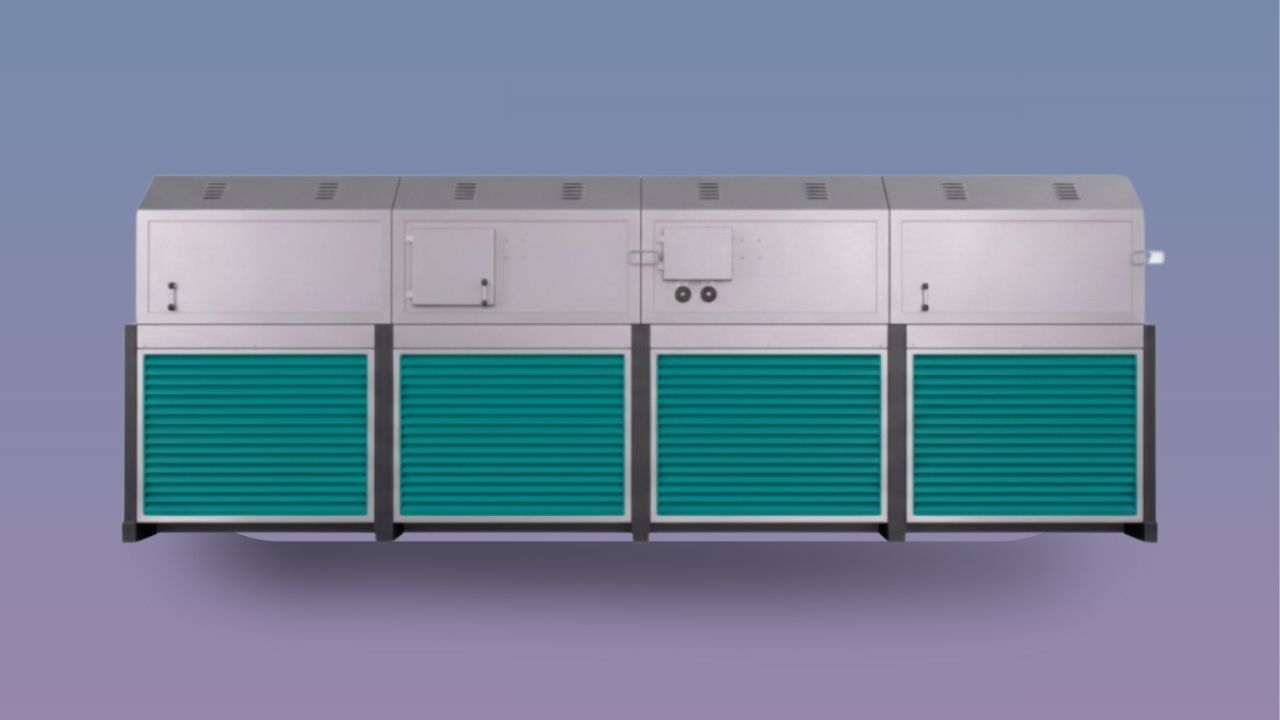

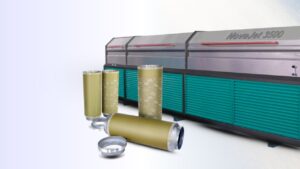

NovaJet introduces a simple but powerful idea — replace all harmful chemicals with high-pressure water.

Instead of burning the emulsion with acid, NovaJet cleans screens using a controlled water-jet system. This process removes the hardened emulsion layer fully, without damaging the nickel base.

The result?

A cleaner, safer, faster and eco-friendly way of restoring your rotary screens.

How NovaJet Works (Explained Simply)

- A high-pressure water pump pushes water through 55 precision nozzles.

- The screen rotates while the water jets gently strip away the emulsion.

- No chemicals, no fumes, no corrosion — just water pressure doing the job.

The system is built to handle large workloads while keeping screens safe and intact.

Why NovaJet Is a Game-Changer

NovaJet creates benefits at three levels: the planet, the people, and the printing mill.

1. A Win for the Environment

✔ 100% Chemical-Free Process

No acids. No solvents. No toxic waste.

✔ Huge Reduction in Pollution

Across installations, NovaJet helps save thousands of litres of hazardous chemicals every month.

✔ Low Water Consumption

The optional recycling system allows water to be filtered and reused through a sand-filter tank, reducing water usage dramatically.

For mills working towards sustainable textile production, NovaJet is one of the strongest upgrades they can adopt.

2. A Win for Worker Safety

✔ No exposure to harmful chemicals

✔ No dangerous fumes or burning agents

✔ Clean, safe and comfortable working conditions

NovaJet helps mills meet better safety standards and protect their workforce.

3. A Win for Printing Quality and Cost Savings

✔ Screens Last Much Longer

Because nothing corrodes the nickel surface, screens can be reused many more times — cutting replacement costs.

✔ Better Print Quality

A clean, undamaged screen means sharper prints, consistent quality and fewer production errors.

✔ Fast Cycle Time

Although the official stripping time is 10 minutes, most screens are cleaned within 8 minutes, helping mills keep up with production speed without delays.

Why More Mills Are Switching to NovaJet

Across India and abroad, textile mills are adopting NovaJet because it brings clear benefits:

- Lower running cost

- Zero chemical purchase

- Faster turnaround

- Longer screen life

- Cleaner compliance-friendly operations

- Happier workforce

- Better print consistency

In short, NovaJet helps mills modernize while reducing cost and embracing clean production

Conclusion: The Future of Screen Recycling Is Chemical-Free

NovaJet represents a major shift in how the textile industry handles screen reuse. Instead of dangerous and polluting chemicals, the simple power of high-pressure water delivers a process that is:

- Safe for people

- Safe for the planet

- Beneficial for printing businesses

For mills aiming to reduce costs, improve quality, and stay future-ready, NovaJet is not just a machine — it’s a smarter and more responsible way to work.

Want to Upgrade to Chemical-Free Screen Recycling?

Talk to Bludigit Technologies and explore the NovaJet solution for your mill.

Call Us Now or Send Us an Enquiry

Let’s build a cleaner and more efficient printing future together.