For many years, textile mills have used strong chemicals to remove old emulsion from rotary screens. Yes, the chemicals clean the screens – but they also bring many problems that affect workers, machines and the environment.

Let’s understand these problems in a simple and clear way.

1 Chemical Cleaning Is Unsafe for Workers

The most commonly used chemicals include very strong acids. These can:

- burn skin

- harm eyes

- create dangerous fumes

- affect breathing

Many of these chemicals are already banned in Europe because of their health risks. Workers who handle these chemicals daily face long-term health problems.

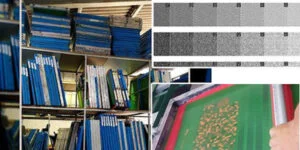

2 Screens Become Weak and Break Faster

Chemicals slowly damage the nickel surface of the rotary screen.

This causes:

- mesh becoming thin

- screens losing strength

- print quality getting poor

- screen life reducing

In short: you spend more money replacing screens again and again.

3 The Environment Gets Damaged

When chemical waste is washed away, it pollutes water and soil.

This increases:

- disposal cost

- risk of government penalties

- negative environmental impact

Today, textile brands expect mills to follow clean and safe processes. Chemical cleaning does the opposite.

Want to know the safer alternative?

Read Part 2: How NovaJet Cleans Screens Using Only Water (No Chemicals).